|

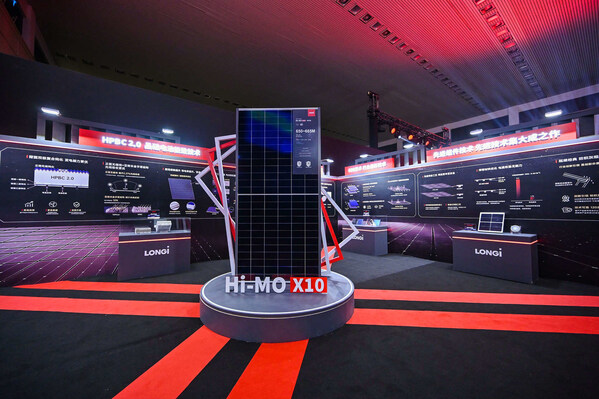

SHANGHAI, Oct. 15, 2024 /PRNewswire/ -- LONGi has officially launched its new generation distributed module product Hi-MO X10 at the Rolex Shanghai Masters. The module, featuring HPBC 2.0 cell technology, marks a milestone upgrade and technological leap for LONGi's BC products.

Hi-MO X10 module is designed for the global distributed market, featuring unparalleled safety, enhanced energy output and exceptional aesthetic quality. In addition to HPBC 2.0 cell technology, it also utilizes TaiRay silicon wafers, achieving a maximum mass production power of 670W, which surpasses mainstream TOPCon modules by over 30W, and a maximum module efficiency of 24.8%. This represents the last generation of crystalline silicon cells to achieve an absolute efficiency leap of 1%, signalling the true arrival of the BC era.

Breaking New Ground: HPBC 2.0 + TaiRay Wafer + 0BB Technology

LONGi's HPBC 2.0 cell technology represents a culmination of advancements in BC technology. In November 2022, the company launched HPBC 1.0, ushering in the BC era and now, two years later, HPBC 2.0 retains the excellent genes of its predecessor, achieving breakthroughs in key areas including cell substrates, passivation technology and manufacturing process technology, with mass production cell efficiency exceeding 26.6%, reflecting an absolute efficiency leap of 1.5% within 2 years and establishing a generational gap with other market cells.

Meanwhile, LONGi has broken through other cell technology barriers, its self-developed Bipolar Hybrid Passivation technology allowing the mass-produced cell open-circuit voltage to exceed 745 mV, leading the industry's mainstream TOPCon products by 15mV, significantly reducing current loss and improving cell conversion efficiency.

Hi-MO X10 incorporates the company's high-quality N-type TaiRay silicon wafers which had achieved substantial breakthroughs over the past decade. TaiRay silicon wafers offer three major advantages: Firstly, high product concentration results in more concentrated high-efficiency cell grading after cell manufacturing. Secondly, the adoption of new processes reduces oxygen content and other impurities, with fewer single-crystal growth defects, enhancing cell efficiency. Thirdly, the wafers have improved breakage resistance, with a 16% increase in bending strength compared to conventional products.

In order to minimize power loss and boost energy generation, Hi-MO X10 features an HPBC 2.0 cell that adopts an innovative 0BB structure, making it completely free of grid lines on the front and busbars on the back. This allows module power to increase by some 5W (taking the 2382×1134mm module size as an example). It also enhances the aesthetic appeal of the cells' back side and improves bifaciality, unlocking greater potential for future double-sided cell and module innovations.

Enhanced Reliability: Anti-shading + Prevention of local overheating + Comprehensive Anti-aging + System-level Stress Resistance

Extreme weather events—high temperatures, alternating droughts and flooding, hurricanes and storms—are on the rise. Solar panels need to withstand these challenges over a 25- to 30-year lifespan, maintaining stable performance to safeguard power plants and maximize returns.

Shading and hotspots present significant risks for distributed solar systems, with nearly 50% of module failures caused by shading and hotspots from rooftops, nearby objects or dirt. When shading occurs, it can block current, causing local temperature spikes and leading to the "hotspot effect" that can both damage the module material and cause risk of fire in a worst case scenario. Hi-MO X10 mitigates such issues with its unique "soft breakdown design" that allows blocked current to bypass shaded or hotspot-affected areas by redirecting it through alternative internal pathways within the cell, reducing power loss by over 70% compared to TOPCon. This design not only minimizes power loss and maximizes energy generation efficiency by effectively rerouting the current, but also lowers hotspot temperatures by 28%, ensuring stable operation and rooftop safety.

Beyond shading, factors such as UV radiation, high temperatures and humidity and temperature fluctuations also challenge a module's long-term performance. The Hi-MO X10, with its low operating temperature and high-density encapsulation, offers comprehensive anti-aging properties and performs exceptionally well under rigorous testing. Compared to TOPCon modules, the Hi-MO X10 product exhibits superior resistance to UV, damp heat and thermal cycling, making it more resistant to heat, moisture and prolonged exposure to the sun. With a temperature coefficient of -0.26%/℃—an improvement of 0.03%/℃ over TOPCon—the product maintains high performance levels, with a first-year degradation rate of 1% and linear degradation of 0.35%, providing customers with a 15-year product warranty and a 30-year power warranty.

Hi-MO X10 also offers exceptional system-level stress resistance and micro-crack prevention, achieved through the superior mechanical properties of TaiRay wafers, which, despite the industry trend toward thinner wafers, remain thicker than most products due to LONGi's commitment to higher standards. Additionally, the module's full back welding structure further reduces the risk of micro-cracks during transportation, installation and operation. According to logistics data, this design lowers the likelihood of micro-cracks by an impressive 87.2%, ensuring reliable performance under a range of environmental stresses and enhancing overall module durability.

All in BC: LONGi's Unwavering Commitment

Each technological breakthrough drives a leap in efficiency leaps and catalyzes industry transformation. According to LONGi Chairman Zhong Baoshen, industry attitudes towards BC technology have shifted this year, with more peers entering the BC arena and seeking collaboration on BC production lines.

Zhong commented: "We firmly believe that BC technology will become the dominant force in crystalline silicon cells, including both bifacial and monofacial designs. In the future, a significant portion of LONGi's product lineup will embrace the BC technology pathway. Our mission is to promote this widely recognized technology platform, which offers high compatibility and excellent weatherability, across a wider range of applications and markets."

About LONGi

Founded in 2000, LONGi is committed to being the world's leading solar technology company, focusing on customer-driven value creation for full scenario energy transformation.

Under its mission of 'making the best of solar energy to build a green world', LONGi has dedicated itself to technology innovation and established five business sectors, covering mono silicon wafers, cells and modules, commercial & industrial distributed solar solutions, green energy solutions and hydrogen equipment. The company has honed its capabilities to provide green energy and has, more recently, also embraced green hydrogen products and solutions to support global zero carbon development. www.longi.com

source: LONGi

想要獨家投資理財Tips?即Like etnet 全新Facebook專頁► 立即讚好